24 years of professional research and development, production of chemical silicone products

Methyl Phenyl Silicone Resin for heat resistant paints

SH-9601 Methyl Phenyl Silicone Resin for heat resistant paints

Product Description

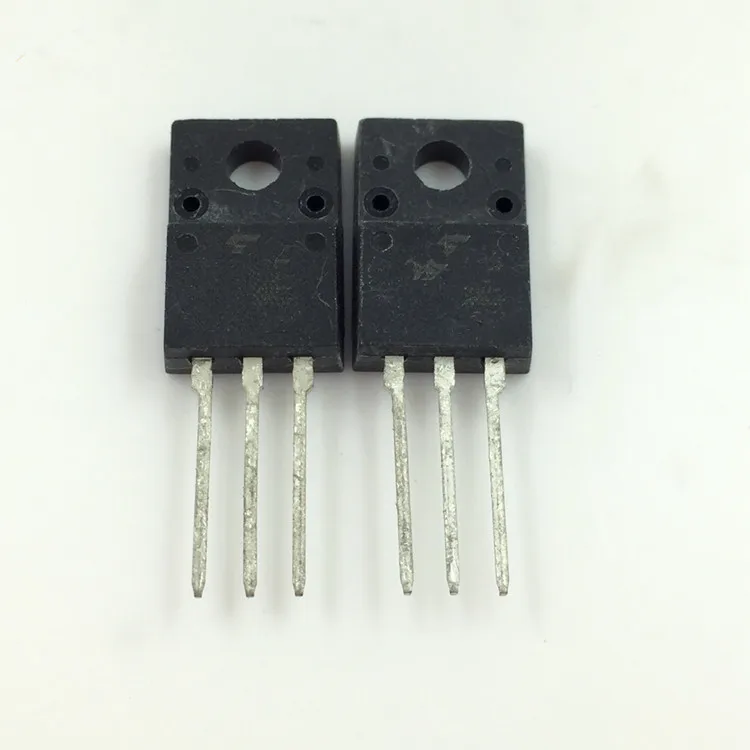

SH-9601 Methyl Phenyl Silicone Resin for heat resistant paints for H - grade motor/Transformer coil/Transistor sealing/H - grade glass wire dipping

I,Main Composition

Methyl phenyl silicone resin

II,Technical Index

| Item | Index | |

| Appearance | Light yellow or red brown liquid, opalescence is permitted, no mechanical impurity | |

| Solid content((150℃,2h,%) | 50±1 | |

| Viscosity (4# cup,25℃,S) | no less than 15 | |

| Drying Time(200℃,Copper Sheet, h) | No more than 2 | |

| Mass Loss(400℃,3h,%) | No more than 5 | |

| ElectricalBreakdown Strength (KV/mm, no less than) | Normal(20±5℃) | 65 |

| High temperature (200±2℃) | 30 | |

| Become Damp(20±5℃,relative humidity 95%,after 24h) | 40 | |

| Volume Resistance(Ω.cm, no less than) | Normal(20±5℃) | 10 |

| High temperature (200±2℃) | 10 | |

| Become Damp(20±5℃,relative humidity 95%,after 24h) | 10 | |

|

|

III,Performance and usage

This product has excellent heat resistance, electrical insulation and moisture resistance.

It is suitable for H - grade motor, transformer coil, transistor sealing, H - grade glass wire dipping and heat or high temperature resistant coating etc.

|

|

|

|

|

Packaging, Storage & Delivery

Be packed in clean, dry 20kg and 200kg iron drums and sealed. Stored in cool ventilated and dry environment under the temperature 35℃. Avoid sun exposure and closing to the heat sources. Stored and transported as flammable goods.

Model: SH-9601 Methyl Phenyl Silicone Resin for heat resistant paints

Supply Capacity: 500 Tons each month

Package: Be packed in clean, dry iron drums and sealed